The Benefits of Lithium Iron Phosphate Batteries

Batteries made of lithium iron phosphate (LiFePO4) are at the forefront of battery technology. The batteries are cheaper than most of their rivals and do not contain the toxic metal cobalt. They are non-toxic and have a long shelf life. For the near future, the LiFePO4 battery offers excellent promise. Batteries made of lithium iron phosphate are highly effective and sustainable.

When not in use, a LiFePO4 battery self-discharges at a rate of just 2% per month as opposed to 30% for lead-acid batteries. It takes less than two hours to fully charge. Lithium-ion polymer (LFP) batteries have four times higher energy density when compared to lead-acid batteries. These batteries can be charged quickly because they are available at 100% of their full capacity. These factors contribute to the high electrochemical efficiency of LiFePO4 batteries.

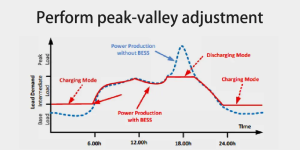

The use of battery energy storage equipment may enable businesses to spend less on electricity. Extra renewable energy is stored in the battery systems for later use by the business. In the absence of an energy storage system, businesses are compelled to purchase energy from the grid rather than using their own previously developed resources.

The battery continues to deliver the same amount of electricity and power even when it is only 50% full. Unlike their rivals, LFP batteries can operate in warm environments. Iron phosphate has a strong crystal structure that resists breakdown during charging and discharging, resulting in cycle endurance and a longer lifespan.

The enhancement of LiFePO4 batteries is caused by a number of factors, including their lightweight. They weigh about half as much as regular lithium batteries and seventy percent as much as lead batteries. When a LiFePO4 battery is used in a vehicle, gas consumption is decreased and maneuverability is improved.

An Ecologically Friendly Battery

Since the electrodes of LiFePO4 batteries are made of non-hazardous materials, they pose significantly smaller harm to the environment than lead-acid batteries do. Each year, lead-acid batteries weigh more than three million tons.

Recycling LiFePO4 batteries allow for the recovery of the material used in their electrodes, conductors, and casings. The addition of some of this material could help new lithium batteries. This particular lithium chemistry can endure extremely high temperatures, making it ideal for energy projects like solar energy systems and high-power applications. The possibility of buying LiFePO4 batteries made from recyclable materials is available to consumers. Although recycling processes are still being developed, a substantial number of lithium batteries used for energy transportation and storage are still in use due to their extended lifespan.

Numerous LiFePO4 Applications

These batteries are used in many different contexts, such as solar panels, cars, boats, and other purposes.

The most reliable and secure lithium battery for commercial use is LiFePO4. They are therefore perfect for commercial uses like liftgates and floor machines.

The LiFePO4 technology is applicable to many different fields. Fishing in kayaks and fishing boats takes more time when the runtime and charge time are longer and shorter, respectively.

A recent study on lithium iron phosphate batteries uses ultrasound.

Every year, there are more and more used lithium iron phosphate batteries. If these batteries are not disposed of in a timely manner, they will cause environmental contamination and eat up a lot of metal resources.

The majority of the metals that go into the construction of lithium iron phosphate batteries are found in the cathode. An essential phase in the process of recovering depleted LiFePO4 batteries is the ultrasonic method.

High-speed photography, Fluent modeling, and the disengagement process were used to investigate the airborne bubble dynamic mechanism of ultrasonic in the elimination of lithium phosphate cathode materials in order to get beyond the limitations of the LiFePO4 recycling method. The recovered LiFePO4 powder has outstanding electrochemical properties and the lithium iron phosphate recovery efficiency was 77.7%. Waste LiFePO4 was recovered using the novel disengagement technique created in this work.

Technology for Enhanced Lithium Iron Phosphate

LiFePO4 batteries are good for the environment because they can be recharged. When it comes to storing renewable energy, batteries are effective, trustworthy, safe, and green. Novel lithium iron phosphate compounds may be created further using the ultrasonic method.