Aluminium lithium ion battery case:

Aluminum case lithium ion battery energy density is higher than plastic case. Aluminum case itself is because the metal case, so I need insulation; Plastic case itself has insulation performance, end cover is easy to carry, more convenient packaging, but its energy density is lower than the aluminum case.

Because the aluminum case lithium-ion batteries has the relative advantage, aluminum case lithium ion battery is the mainstream of the current liquid lithium ion battery used in almost all areas of the lithium ion battery related. Lightweight and security, and the resulting performance advantage, make the lithium ion battery has become the mainstream in the case, aluminum case and aluminum case lithium-ion batteries is to high hardness, lightweight technology development, which will provide aluminum case lithium-ion batteries with excellent technical sales of lithium ion battery products.

Plastic lithium ion battery case:

Using the plastic case. It is important that different lithium ion battery pack after molding, case may need to be involved in the molding. The mould cost is a big cost. If there is no finalize the design product in the early stage of development, prototype case can be used for proofing (prototype) strength than the strength of the material after open mold molding), as well as the requirement to the prototype of case materials and technology (especially the three prevention requirements) is different, also affect the cost.

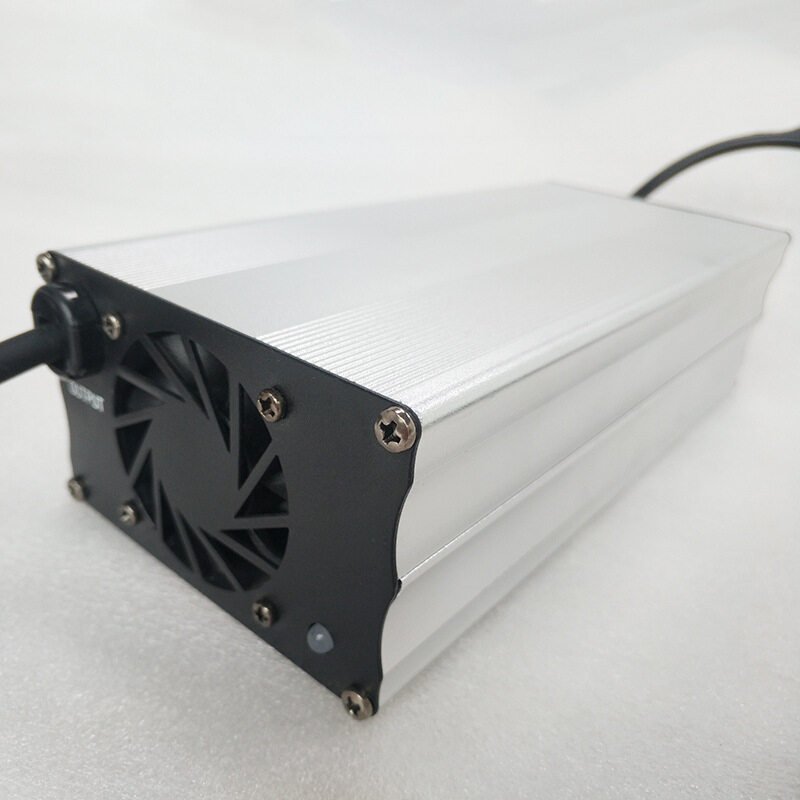

Metal lithium ion battery case:

Metal case and plastic case. In front of the product or quantity demand is not big, the proposal USES sheet metal sample preparation. This is very important, because the sample preparation time is short. If large quantities, also suggested that open mould. For metal jacket waterproof level requirements, the cost will be affected by a lot, if you need any special materials (such as titanium alloy, etc.) of the metal case, the cost will be higher.

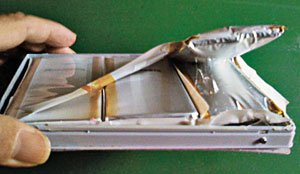

Lithium ion battery Pool case bulge

Lithium battery after batteries charged to 4.2 V voltage, will start to appear a sideline. The higher the charging voltage, the higher the risk. When lithium batteries, battery voltage is higher than 4.2 V, the rest of the anode material of lithium atom number less than half. At this time, the battery tends to collapse, causing the battery capacity decline. If continue to charge, as a result of the cathode of lithium battery is full of atoms, and the subsequent lithium will accumulate on the surface of the cathode materials.

These lithium atoms from the cathode surface in the direction of the lithium ion dendrite growth. These lithium metal crystal will through the isolation of paper, that is negative short circuit. Sometimes the battery in the event of a short circuit before it exploded. This is because in the process of overcharge, electrolyte and generate gas and other material will burst, causing the battery case or inflation pressure valve is broken, and let the oxygen to and react with lithium atoms on the surface of the accumulation in the cathode. Then exploded.

In to lithium ion batteries, therefore, must set the upper limit of voltage, so that both the life of the battery, capacity and security. The ideal maximum charging voltage of 4.2 V. Lithium battery discharge have voltage limit. When the battery voltage is lower than 2.4 V, some materials will start to be destroyed. And because the battery self-discharge, place the longer, lower voltage. Therefore, it is best not to stop when the battery discharge to 2.4 V. Lithium ion battery during discharge from 3.0 V to 2.4 V, the energy released only accounted for about 3% of battery capacity. Therefore, 3.0 V is the ideal discharge cut-off voltage. Charge and discharge, in addition to the pressure limiting, current limiting is needed. When the current is too large, lithium ion too late into the battery, will be piled up in the material surface.

These acquired electronic lithium ion, lithium atoms in the material surface, just like the overcharge, can cause dangerous. If the battery case is broken, and it will explode.

Conclusion:

Lithium-ion batteries, aluminum, steel case, plastic case each have advantages and disadvantages, can’t simply to judge. Depending on the usage and judgment standard.

The protection of the lithium ion battery must include at least three: charging voltage upper limit and lower limit discharge voltage and current limit. Generally speaking, in a lithium-ion battery pack, in addition to lithium ion batteries, there would be a protection board. The protection plate is very important to provide these three protection. Protection board, however, these three protection apparently wasn’t enough, the lithium ion battery explosion accidents still occur. In order to ensure the safety of battery system, analysis of battery explosion causes more carefully.

If you want to know more about lithium battery, please contact Maxworld Power.