How to install lithium boat batteries

Installing a lithium-ion battery bank is the current answer for increased electrical demand on blue sea cruising yachts, especially if one intends to stop using LPG for cooking.

However, installing lithium-ion batteries can be difficult and complicated, and if done incorrectly, it poses a significant fire danger.

To begin with, currently the safe lithium-ion battery cell recommended for use on a boat is lithium-iron-phosphate (LiFePO4), also known as LFP.

Although they can still catch fire (as can any battery) if positioned or used incorrectly, these cells have undergone extensive testing by fire authorities in several nations and are generally fireproof on their own.

For usage on a boat, it is strongly advised against using automotive lithium-ion blends that contain nickel, cobalt, and manganese because they are much more likely to experience “thermal runaway” if they malfunction.

As there is no practical method to transfer the same intricate protective mechanism that previous electric car batteries were originally built to function under, this effectively rules out the use of those batteries.

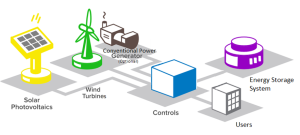

Higher voltage systems (often 48V, 72V, or 96V) are typically used in electrically propelled yachts, necessitating properly designed control systems.

Although it would be enticing to use lithium-ion battery cells with a higher energy density for these applications, such as Lithium Cobalt (LiCoO2), doing so would be highly expensive and need professional design and installation.

Furthermore, why would you install this type of battery on your yacht if you can’t get insurance for it?

The advantages of LFP batteries

LFP batteries offer two key advantages over lead-acid (LA) batteries: they will accept a very quick, high-current recharge and can be depleted practically to emptiness without needing a regular recharge to 100% State of Charge (SOC).

In fact, they are generally content to occupy a SOC position between 20% to 80%. Although the majority of built-in Battery Management Systems (BMS) will shut them off at about 12V, which is comparable to about 10% SOC, you can even totally empty LFP without harming them.

The BMS should automatically turn off the charging source at about 14.2V, in order to prevent overloading, when they are completely charged.

Additionally, LFP batteries will offer many more charge cycles than an equivalent-capacity LA battery. Finally, they are also significantly lighter than any sort of LA battery, which can have a significant impact on the balance and performance of a sailing yacht.

LFP conversion?

Any connected wiring and circuit protection for LFP batteries must be capable of handling and customized for the task given their capacity to take and discharge very large currents.

It’s also important to keep in mind that it may not always be possible to connect more than two so-called “drop-in” LFP batteries (those having an inherent BMS) together in series or parallel to make a larger bank.

If you need additional capacity, it is usually preferable to build a custom bank out of separate 3.2V cells and add a single external BMS to operate the entire bank concurrently.

You must purchase brand-new, grade A cells if you wish to assemble your own battery bank from individual cells.

Many of the cheap online purchases from China are second-hand cells that are frequently replaced in an Uninterruptible Power Supply (UPS) or other similar device used by a data storage bank.

Despite the possibility of luck, it really isn’t worth the chance because it will be nearly impossible to get your money back.

It is ideal for the cells to have had capacity tested and to arrive at a voltage level that is relatively similar, but you must initially balance them to be certain.

Although it is feasible, it isn’t recommended to employ LFPs for bow thruster and anchor windlass operation. Most won’t function regardless since the instantaneous, high current demands of these devices frequently surpass the output threshold of their BMS.

The part of an LFP installation that raises the most questions is how to correctly configure the device for charging.

Personal and practical judgments must be made as with other things on a boat, and many of these may change based on the size and type of boats.

Improving cell longevity

LFP batteries can be charged and discharged at significantly higher rates—even up to 1C—than Lead-Acid (LA) kinds because they have much lower resistance (1 x capacity, or 100A for a 100Ah battery).

Charging must halt when the charge current falls to between 0.015C and 0.03C in order to prevent overcharging the batteries. However, they are typically charged at between 0.5C and 1.0C up until that point.

Some manufacturers even advise that you stop charging at 0.1C to further reduce battery stress and lengthen their lives. Since the SOC can peak when the LFP battery is only halfway charged, it cannot be identified only by battery voltage. In addition, a completely charged 12.8V LFP battery has a resting voltage of 13.4V–13.6V, which is significantly higher than the 12.7V of a typical lead–acid battery. When a LA battery should be at 11.8V, it will still read 13V at 20% SOC.

Battery charging

1.

How to set up alternator charging to fit your installation and any current equipment you intend to keep is one of the most perplexing aspects of an LFP upgrade.

Due to its extremely low internal resistance, an LFP battery will take as much current as it can from the alternator. The alternator winding would eventually die from overheating if this were to go unchecked.

You will probably overload the alternator, the voltage sensing relay (VSR), if you leave a LA engine start battery connected directly to the alternator output and charge the LFP leisure bank instead of the LA domestic battery bank using a VSR. In reality, even if the VSR were to survive this condition, it would not function as it should because the relay would have to stay constantly engaged due to the higher resting voltage of the LFP.

Installing an external smart alternator regulator is one suggested remedy. This device will be equipped with temperature sensors for the battery and alternator, and it will regulate the charge as necessary to keep the alternator within a safe operating temperature range while allowing the LFP bank to receive the maximum amount of charge.

2.

Installing a DC-DC (B2B) charger between the start battery and the LFP house bank while charging the start battery directly from the alternator is a popular strategy for its simplicity.

The main benefit of this approach is that a DC-DC charger will keep the alternator’s and start battery’s current usage to a minimum while also guaranteeing that the output charge parameters are perfectly compatible with the LFP house bank.

Additionally, because it may continue to charge the start battery normally even if the LFP BMS shuts down for whatever reason, the alternator diodes are safeguarded.

The only significant drawback is that the amount of charge that can be sent to the bank will be constrained by the maximum output of the DC-DC charger. If a higher total charge current is needed, this drawback can be avoided by connecting multiple DC-DC chargers in parallel.

Regulated temperature

1.

I recently learned about a technique known as the “shoestring,” sometimes known as “long wire regulation.”

It entails directly connecting the alternator, which has an integrated regulator, to the LFP bank, adjusting the cable’s diameter and length to control the amount of current drawn, and figuring out the necessary resistance using Ohm’s law in order to lower the charge current to a level that is within the alternator’s safe working load limits. While this principle holds true, utilizing a wire as a resistor will cause the wire to heat up and is not advised by professional maritime electrical organizations. It is also unlikely that insurance companies would support this practice in the event of an accident.

2.

One issue with LFP batteries of the “drop-in” variety is that the BMS will just stop providing power to the battery when it determines that it is completely charged.

It will be acceptable whether this is a solar or DC-DC charger. However, if it’s your alternator, stopping the load right away will surely destroy its output diodes.

Finally, it’s crucial to keep in mind that LFP batteries won’t receive any charge at 0°C or lower.

You must thus set your battery box onto heat pads to maintain a temperature of 5°C or higher if it frequently lowers to that level.

They will eventually accept payment, but there will be considerable power usage as a result.

When switching to LFP batteries, there is another crucial physical consideration to keep in mind.

You must make sure your drive belt can handle the increased alternator load caused by the higher charging rates.

Make that the belt is the right kind, in good shape, and is tensioned properly.

Only alternators rated up to 75A can use a normal vee-belt.

Above this, a powerful belt and pulleys, such as the multi-channel serpentine belt drive, are needed.

Various battery configurations

The following are the top three installation techniques for LFP house batteries and LA engine start:

Solar energy or an alternator can charge a house battery. Pros: Lowest failure risk; simple and safe. Cons: Any extra charge would be wasted once each battery has reached its full capacity.

Solar to start the house, the alternator to start the battery, or a DC-DC charger to start the house. Positives: House LFP are charged to the proper LFP settings and the alternator is safeguarded against unexpected disconnections. Cons: Maximum charge rate is restricted by DC-DC chargers.

DC-DC from the house to the start battery via the alternator and solar power. Positives: Faster charging due to LFP house bank’s maximum charge. Cons: External alternator regulating is necessary to prevent alternator overheating.