Addressing the Recycling Challenge: Sustainable Practices for Lithium-Ion Batteries

The rapid proliferation of lithium-ion batteries, driven by the surge in electric vehicles (EVs) and renewable energy systems, has brought forth the critical challenge of recycling. Recyclers of lithium-ion batteries must use sustainable methods to reduce their negative effects on the environment, conserve resources, and promote a circular economy. This article delves into the recycling challenges associated with lithium-ion batteries and explores sustainable practices to address them.

1. The Growing Tide of Lithium-Ion Battery Waste:

- Explosive Market Growth:

E-Waste Concerns: The surge in lithium-ion battery production has led to a corresponding increase in electronic waste (e-waste) containing these batteries.

End-of-Life Management: Proper management of end-of-life batteries is crucial to prevent environmental hazards.

- Complex Composition:

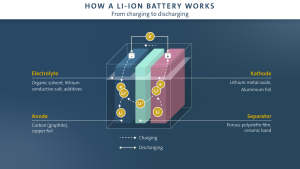

Multifaceted Components: Lithium-ion batteries comprise various materials, including metals like lithium, cobalt, nickel, and complex electrolytes.

Challenges in Separation: Efficient recycling involves separating and recovering these materials, presenting technical challenges.

2. Recycling Technologies and Processes:

- Hydrometallurgical Processes:

Chemical Extraction: Chemical procedures are used in hydrometallurgical technologies to remove metal from battery components.

Selective Recovery: The recovery of precious metals such as nickel, cobalt, and lithium may be done selectively thanks to these techniques.

- Pyrometallurgical Processes:

Thermal Treatment: Pyrometallurgical methods use high-temperature processes to recover metals from battery materials.

Energy-Intensive: While effective, these processes can be energy-intensive, necessitating careful consideration of environmental trade-offs.

3. Battery Design for Recyclability:

- Modular Design:

Ease of Disassembly: Designing batteries with modular components facilitates easy disassembly during recycling.

Separation of Materials: Modularity allows for efficient separation of various components, streamlining the recycling process.

- Standardized Connectors:

Facilitating Disconnection: Standardized connectors and interfaces simplify the disconnection of batteries from electronic devices or vehicles.

Reducing Contamination: Proper disconnection minimizes the risk of contamination during recycling.

4. Innovative Recovery Techniques:

- Advanced Sorting Technologies:

Automated Sorting: The efficiency of material separation is improved by new technology, such as automated sorting machines.

Machine Learning Applications: Machine learning algorithms contribute to accurate identification and sorting of different battery components.

- Direct Recycling Approaches:

Avoiding Intermediate Steps: Direct recycling approaches aim to minimize intermediate processes, making the recycling chain more efficient.

Reducing Environmental Footprint: By eliminating certain steps, direct recycling can reduce the environmental footprint of the recycling process.

5. Strategic Partnerships and Collaborations:

- Industry Cooperation:

Shared Responsibility: Strategic collaborations among battery manufacturers, recycling facilities, and government bodies promote shared responsibility for end-of-life management.

Pooling Expertise: Collaborative efforts allow the pooling of expertise and resources to address recycling challenges comprehensively.

- Research Initiatives:

Innovation Through Research: Ongoing research initiatives focus on developing new and more sustainable recycling technologies.

Public-Private Partnerships: Collaborations between research institutions, industry players, and government agencies drive innovation in recycling practices.

6. Circular Economy Models:

- Closed-Loop Systems:

Circular Supply Chains: Implementing closed-loop systems ensures that recycled materials are reintegrated into new battery production.

Reducing Dependency on Raw Materials: Closed-loop systems contribute to a more sustainable battery industry by reducing the reliance on virgin raw materials.

- Extended Producer Responsibility (EPR):

Producers’ Role in Recycling: EPR programs make manufacturers responsible for the end-of-life management of their products, encouraging sustainable design and recycling practices.

Financial Incentives: Financial incentives and penalties encourage manufacturers to design products with recycling in mind.

7. Public Awareness and Participation:

- Consumer Education:

Promoting Responsible Disposal: Educating consumers about the importance of proper disposal and recycling of batteries is crucial.

Collection Programs: Public awareness campaigns and convenient collection programs enhance consumer participation in recycling initiatives.

- Incentives for Recycling:

Reward Programs: Introducing incentive programs, such as trade-ins or discounts for recycling old batteries, encourages consumers to actively participate in recycling efforts.

Creating a Recycling Culture: Incentives contribute to the creation of a recycling culture, fostering environmental consciousness.

8. Environmental and Economic Benefits:

- Reducing Resource Depletion:

Conserving Valuable Metals: Effective recycling minimizes the need for mining and extraction by preserving important metals like nickel, cobalt, and lithium.

Mitigating Environmental Impact: By decreasing the demand for raw materials, recycling helps mitigate the environmental impact associated with mining activities.

- Job Creation in Recycling Industry:

Emerging Job Opportunities: The growth of the recycling industry, driven by increased battery recycling, creates job opportunities in collection, sorting, and processing.

Green Economy: Recycling contributes to the development of a green economy with job roles focused on sustainability.

9. Regulatory Frameworks and Standards:

- Mandatory Recycling Regulations:

Legal Obligations: Governments worldwide are implementing or strengthening regulations mandating the recycling of batteries.

Setting Standards: Regulatory frameworks set standards for environmentally responsible disposal and recycling practices.

- International Cooperation:

Harmonizing Standards: International cooperation helps harmonize recycling standards, fostering consistency in practices across borders.

Addressing Global Challenges: Collaborative efforts address global challenges related to battery waste, ensuring a unified approach to recycling.

10. Investments in Recycling Infrastructure:

- Infrastructure Development:

Recycling Facilities: Investments in advanced recycling facilities and infrastructure enhance the capacity and efficiency of the recycling process.

Logistics and Transportation: Establishing efficient logistics and transportation systems ensures the smooth flow of batteries from collection points to recycling facilities.

- Technological Upgradation:

Adopting State-of-the-Art Technologies: Continuous investments in technological upgrades enable the adoption of state-of-the-art recycling technologies.

Efficiency and Safety: Technological advancements contribute to the efficiency and safety of the recycling process.

11. Conclusion: A Sustainable Path Forward:

A sustainable and ethical energy future depends on finding a solution to the recycling problem as the demand for lithium-ion batteries rises. Through use of cutting-edge technology, circular economy frameworks, and cooperative methods, the sector may establish a closed-loop system that reduces its negative effects on the environment and optimizes the reuse of precious resources. Sustainable practices for lithium-ion battery recycling not only contribute to resource conservation but also foster a holistic approach to environmental stewardship, making a positive impact on both present and future generations.