Introduction

Lithium-ion batteries have become an indispensable part of modern life, powering everything from smartphones and laptops to electric vehicles and renewable energy storage systems. However, the rise in demand for these batteries has led to growing concerns about the environmental impact of their disposal. Recycling lithium-ion batteries is essential to recovering valuable materials, reducing reliance on mining, and minimizing environmental harm. In recent years, significant advancements have been made in lithium-ion battery recycling techniques, making the process more efficient, cost-effective, and sustainable.

This article explores the current state of lithium-ion battery recycling, the advancements in recycling technologies, and the challenges that remain in scaling up these solutions.

1. The Importance of Lithium-Ion Battery Recycling

As the world transitions toward cleaner energy and electric mobility, the production and disposal of lithium-ion batteries have increased exponentially. This surge creates both an environmental and economic challenge.

1.1. Environmental Concerns

Lithium-ion batteries contain materials like lithium, cobalt, nickel, and manganese, which are not only finite but also harmful to the environment if improperly disposed of. When these batteries end up in landfills, they can leak toxic substances, contaminating soil and water. Recycling reduces the environmental risks associated with battery waste while conserving natural resources.

1.2. Material Scarcity

Many of the materials used in lithium-ion batteries, particularly cobalt and lithium, are limited in supply. Extracting these materials from the Earth is not only expensive but also harmful to the environment. As demand for batteries grows, recycling offers a way to recover these valuable resources, reducing the need for new mining activities.

1.3. Economic Benefits

Recycling lithium-ion batteries is becoming increasingly cost-effective. The process allows for the recovery of critical materials that can be reused in the production of new batteries, reducing production costs. Additionally, as electric vehicles (EVs) become more widespread, recycling will help meet the growing demand for battery materials without placing additional strain on global supply chains.

2. Traditional Recycling Methods

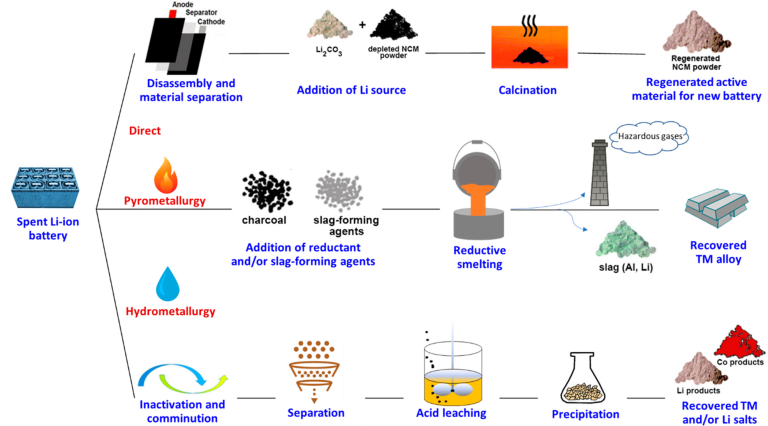

Historically, lithium-ion battery recycling has relied on two primary methods: pyrometallurgy and hydrometallurgy. While these methods have been effective, they also come with significant drawbacks in terms of energy consumption, efficiency, and environmental impact.

2.1. Pyrometallurgy

Pyrometallurgy involves smelting batteries at high temperatures to recover valuable metals like cobalt, nickel, and copper. While this method is efficient at extracting certain metals, it has several disadvantages:

- Energy Intensive: The smelting process requires significant amounts of energy, making it costly and environmentally harmful.

- Loss of Materials: Pyrometallurgy often results in the loss of critical materials such as lithium and aluminum, which are either destroyed or not recovered during the process.

- Emissions: The high-temperature process generates harmful emissions, contributing to air pollution and carbon footprint.

2.2. Hydrometallurgy

Hydrometallurgy, on the other hand, uses chemicals to dissolve the battery components, allowing for the extraction of valuable metals. This method has some advantages over pyrometallurgy:

- Lower Energy Use: Hydrometallurgy consumes less energy than pyrometallurgy, making it a more environmentally friendly option.

- Better Material Recovery: It is more effective at recovering lithium, cobalt, and other critical materials.

However, hydrometallurgy still relies on the use of hazardous chemicals, which pose environmental and safety risks.

3. Advancements in Recycling Technologies

To address the limitations of traditional recycling methods, researchers and companies have been developing new technologies and techniques that are more sustainable, efficient, and scalable. These advancements are transforming the way lithium-ion batteries are recycled and promise to play a key role in the circular economy of battery production.

3.1. Direct Recycling

Direct recycling is an emerging technique that focuses on preserving the structure and composition of battery components rather than breaking them down into their elemental forms. This method involves refurbishing cathode materials, such as lithium cobalt oxide (LCO) or lithium nickel manganese cobalt oxide (NMC), and reusing them in new batteries.

- Preserving Cathode Materials: By retaining the integrity of the cathode materials, direct recycling avoids the need for complex and energy-intensive refining processes, making it more cost-effective and environmentally friendly.

- Improved Efficiency: Direct recycling has the potential to recover a higher percentage of the battery’s materials, including lithium, which is often lost in traditional methods.

- Scalability: While still in the early stages of development, direct recycling offers a scalable solution for the growing number of end-of-life batteries, particularly from electric vehicles.

3.2. Solvent-Based Recycling

Solvent-based recycling is another promising advancement in lithium-ion battery recycling. This process uses non-toxic solvents to dissolve and separate the battery components, allowing for the recovery of materials such as lithium, cobalt, and manganese without the need for high temperatures or hazardous chemicals.

- Lower Environmental Impact: The use of non-toxic solvents makes this process more environmentally friendly compared to traditional methods.

- Selective Material Recovery: Solvent-based recycling allows for the selective recovery of specific materials, improving the purity and quality of the recovered components.

- Reduced Energy Consumption: By eliminating the need for smelting or harsh chemicals, this method significantly reduces energy consumption, making it a more sustainable option.

3.3. Mechanical Separation Techniques

Mechanical separation techniques involve physically breaking down the battery components and separating them based on their material properties, such as density or magnetic properties. This method can be used in conjunction with other recycling processes to improve material recovery rates.

- Low Energy Use: Mechanical separation requires less energy than chemical processes, reducing the overall environmental impact.

- Enhanced Material Recovery: This technique can be particularly effective at recovering materials like aluminum, copper, and plastics that are often lost in traditional recycling methods.

3.4. Bioleaching

Bioleaching is an innovative approach that uses bacteria to extract valuable metals from lithium-ion batteries. This process is still in the experimental stage but shows great promise due to its low environmental impact and cost-effectiveness.

- Eco-Friendly: Bioleaching relies on natural bacteria to break down battery materials, eliminating the need for harmful chemicals or high temperatures.

- Cost-Effective: The use of microorganisms makes bioleaching a potentially low-cost recycling method, especially for large-scale operations.

- High Recovery Rates: Early research suggests that bioleaching can recover a significant portion of valuable metals, including lithium and cobalt.

4. Challenges and Future Directions

Despite these advancements, several challenges remain in scaling up lithium-ion battery recycling to meet global demand. Key issues include:

4.1. Collection and Sorting

Efficient collection and sorting of end-of-life batteries is a significant hurdle in the recycling process. Many batteries are disposed of improperly, making it difficult to recover valuable materials. Improved infrastructure for battery collection, as well as public awareness campaigns, are essential to addressing this challenge.

4.2. Economic Viability

While new recycling techniques are promising, many are still in the early stages of development and may not yet be economically viable at scale. Further research and investment are needed to reduce costs and improve the scalability of these technologies.

4.3. Standardization

The lack of standardization in battery design complicates the recycling process, as different battery chemistries and formats require different recycling methods. Developing standardized battery designs could simplify the recycling process and improve material recovery rates.

Conclusion

Advancements in lithium-ion battery recycling techniques are paving the way for a more sustainable and efficient approach to managing the growing volume of end-of-life batteries. From direct recycling and solvent-based processes to mechanical separation and bioleaching, these innovations hold the potential to significantly reduce the environmental impact of battery disposal while recovering valuable materials for reuse. However, challenges such as collection infrastructure, economic viability, and standardization must be addressed to fully realize the benefits of these technologies. As the demand for lithium-ion batteries continues to rise, so too will the importance of developing robust recycling solutions that contribute to a circular economy in energy storage.